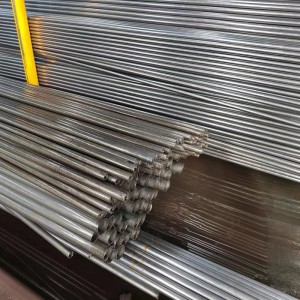

ASTM A335 Alloy Seamless Pipe Low Alloy Steel Seamless Alloy Steel Tube

Short Description:

ASTM A335 is often called as chrome moly pipe because of the chemical contain of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel and Chromium (or chrome) is the essential constituent of stainless steel. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petrol chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for ASTM A335 Alloy Seamless Pipe Low Alloy Steel Seamless Alloy Steel Tube, We look ahead to receiving your enquires quickly and hope to have the chance to get the job done together with you inside the future. Welcome to get a seem at our organization.

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for ASTM A335 Alloy Steel Pipe, Welcome to visit our company, factory and our showroom where displays various hair solutions that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Be sure to contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Strong resistance to rupturing at high temperatures and high pressures.

May be used for Hydrogen Sulfide Corrosion Services.

Resistant to cracking from hydrogen attack and embrittlement.

Resistant to hot sulfide corrosion cracking.

Can be used for NACE Applications where sour environments are under high temp and pressure.

Can be used in NACE-MRO 175 Sour Service.

Ideal for creep rupture applications.

Can handle high temperatures with very low elasticity.

The types of alloy steel covered by the ASTM A335 – ASME SA335 specification are designed with a “P” prefix, from P5 to P92. Grades P11/P22 and P91/92 are typically found in power stations, whereas grade P5 and P9 are more common for application in the petrochemical industry. Grades P9, P91 are, in the list, the more expensive

| ASTM A335Low-Alloy Steel(Grade) | UNS equivalent | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~0.60 |

| A335 Low-Alloy Pipe | UNS Number | Yield Strength ksi | Tensile Strength ksi | Elongation % | Hardness | |

| Rockwell | Brinell | |||||

| P1 | K11522 | 30 | 55 | 30 | – | – |

| P2 | K11547 | 30 | 55 | 30 | – | – |

| P5 | K41545 | 40 | 70 | 30 | – | 207 max |

| P9 | S50400 | 30 | 60 | 30 | – | – |

| P11 | K11597 | 30 | 60 | 20 | – | – |

| P12 | K11562 | 32 | 60 | 30 | – | 174 max |

| P22 | K21590 | 30 | 60 | 30 | – | – |

| P91 | K91560 | 60 | 85 | 20 | – | – |

Alloy Steel pipe are heat treated to achieve mechanical properties as per the desired alloying element. Below are some of the types of heat treatment.

Normalize Quench and Tempering.

Quench and Tempering.

Normalizing & Hardening.

Transverse/longitudinal: tension and flattening, hardness, bend tests- for material which has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested.

ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC).

Hydro testing: shall be applied to every length of pipe.

The non-destructive electric test is optional.Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers.

ASTM A335 Alloy Seamless Pipe Low Alloy Steel Seamless Alloy Steel Tube

We look ahead to receiving your enquires quickly and hope to have the chance to get the job done together with you inside the future. Welcome to get a seem at our organization.

ASTM A335 Alloy Steel Pipe

Welcome to visit our company, factory and our showroom where displays various hair solutions that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Be sure to contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.