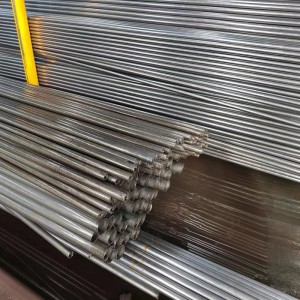

40CrMo 42CrMo 42CrMo4 Aloyi Mapaipi/Machubu

Kufotokozera Kwachidule:

42CrMo aloyi chitoliro chosasunthika ndi chitsulo cholimba kwambiri chokhala ndi mphamvu zambiri komanso kulimba, kulimba kwabwino, kusakhalapo kwamphamvu kodziwikiratu, komanso kupunduka kochepa pakuzimitsa.Pambuyo kuzimitsa ndi kutentha, 42CrMo alloy chitoliro chosasunthika chimakhala ndi malire otopa kwambiri komanso kukana kukhudzidwa kosiyanasiyana, kulimba kwamphamvu pakutentha kochepa, komanso kulimba kwamphamvu kwambiri komanso kupirira kutentha kwambiri.Kuzimitsa pamwamba pambuyo kuzimitsa ndi kutentha kumagwiritsidwa ntchito ngati njira yochizira kutentha kwa mapaipi a 42CrMo aloyi opanda msoko.